Ihlabathi leempendulo ezingxamisekileyo kunye nokhuseleko lwamashishini luxhomekeke kakhulu kwizixhobo ezithembekileyo, ezisebenzayo. Elinye icandelo elibalulekileyo sisixhobo sokuphefumla, umsindisi wobomi kubacimi bomlilo, abaphenduli bokuqala, kunye nabasebenzi abasebenza kwiindawo eziyingozi. Ngokwemveli, ezi zixhobo zazisebenzisa iisilinda zentsimbi ukugcina umoya ophefumlayo. Nangona kunjalo, utshintsho lwenguquko luyaqhubeka ngokukhula kokwamkelwa kwecarbon fiber cylinders. Eli nqaku liphonononga uyilo kunye nenkqubela phambili yobunjineli ngasemvacarbon fiber cylinders kwizixhobo zokuphefumla, iqaqambisa iingenelo abazinikezelayo xa kuthelekiswa noogxa babo bentsimbi.

Amandla adibana nokusebenza kakuhle: Umtsalane weRetio ye-Strength-to-Weight

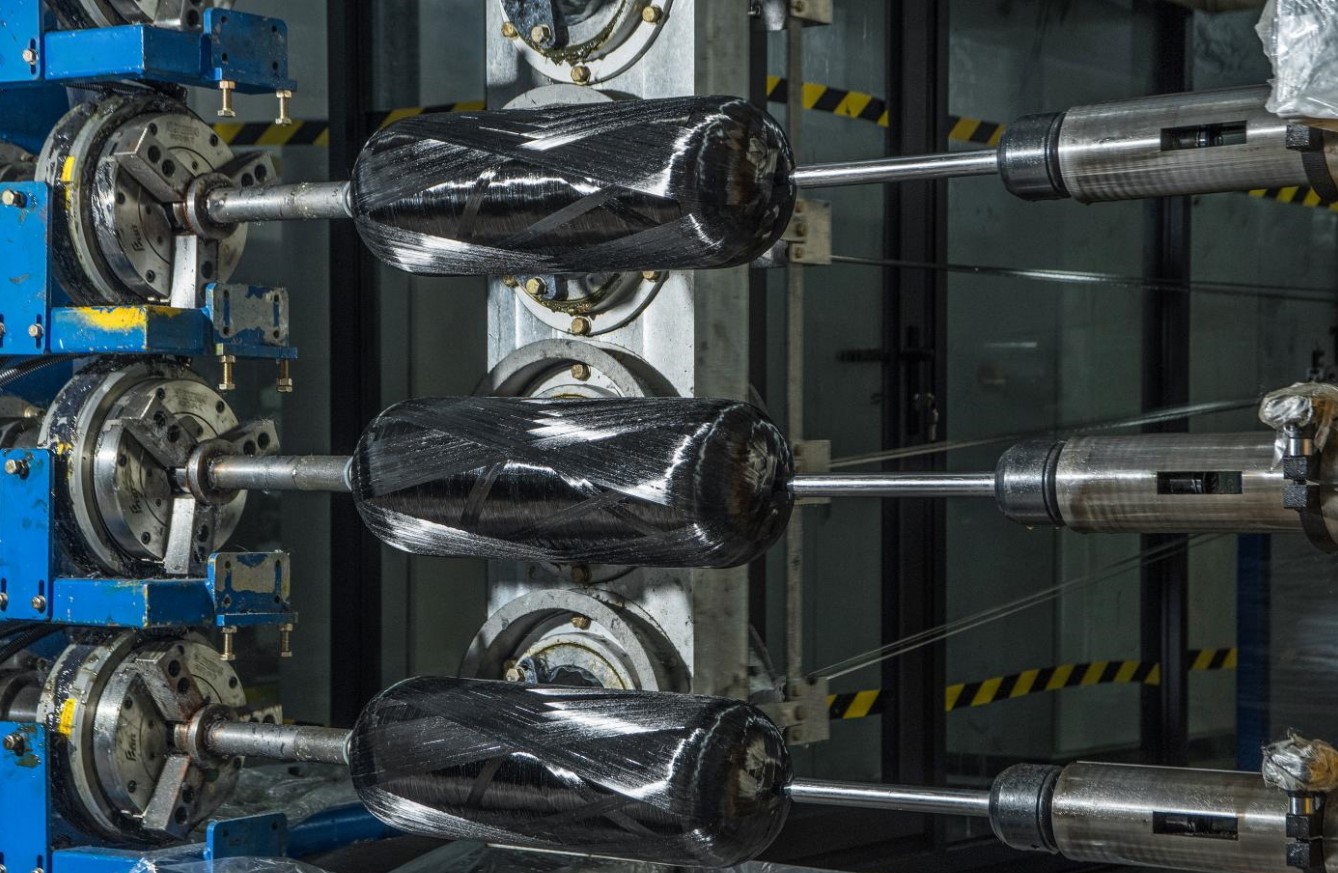

Umqhubi ophambili wokwamkelwacarbon fiber cylinderkwisixhobo sokuphefumla silele kwizinto ezikhethekileyoumlinganiselo wamandla kubunzima. Iintsinga zekhabhoni, ngokwazo zomelele ngokumangalisayo kwaye zikhaphukhaphu, zilukwe ngobunono kwaye zifakwe kwimatrix yeresin ukwenza imathiriyeli edibeneyo. Oku kubangela isilinda esiqhayisa amandla amakhulu ngelixa ihlala ikhanya ngokumangalisayo. Kubacimi-mlilo kunye nezinye iingcali eziphethe izixhobo zokuphefumla ixesha elide, oku kuguqulela kuncedo olukhulu.

Khawube nomfanekiso-ngqondweni womcimi-mlilo esilwa nomlilo, ehamba kwiipaseji ezizele ngumsi ngoxa ephethe izixhobo ezinzima. Yonke i-ounce iyabala. Ukutshintsha iisilinda zentsimbi kunye nezakwabo ezikhaphukhaphu zefayibha kunciphisa ubunzima obupheleleyo bezixhobo zokuphefumla, okukhokelela ku:

Ukudinwa okuNcitshisiweyo:Izixhobo ezilula zivumela ukunyamezela okungcono kunye nokuhamba, okubalulekileyo kwimisebenzi eyandisiweyo.

-Ukuphuculwa kokuLawula:Ubunzima obukhaphukhaphu bongeza ukukwazi komntu onxibileyo ukuhambahamba kwiindawo ezixineneyo okanye ukunyuka iileli ngokulula ngakumbi.

-Ukhuseleko olomeleziweyo:Ukukhathala okuncitshisiweyo kuguqulela ekuphuculeni ukwenza izigqibo kunye nomngcipheko omncinci wokulimala ngexesha leemeko ezinzima.

Oku kuncipha kobunzima kukwanceda abasebenzi bemizi-mveliso abaxhomekeke kwizixhobo zokuphefumla ukuze bangene kwindawo evaliweyo okanye basebenze kwindawo ezinobungozi. Yonke iponti egciniweyo iguqulela ekongezeni kokukhululeka kunye nokuphuculwa kokhuseleko lwabasebenzi.

UYilo lweSikhephe soxinzelelo: iNjineli yoKhuseleko kunye nokuthembeka

Ukunikezelwa komoya ngaphakathi kwesixhobo sokuphefumla kugcinwa kuxinzelelo oluphezulu ukuze kuqinisekiswe umthamo owaneleyo kunye nokuhamba komntu onxibileyo. Oku kufuna uyilo oluqinileyo lwenqanawa yoxinzelelo. Ifayibha yeCarbon, kunye nomlinganiselo wayo okhethekileyo wokomelela kubunzima, inika isisombululo esigqibeleleyo. Iinjineli zinokuyilacarbon fiber cylinders ukuhlangabezana nemigangatho yokhuseleko engqongqo yothintelo loxinzelelo ngelixa ugcina ubunzima buncinci.

Nantsi indlela uyilo olunenyameko oludlala ngayo indima ebalulekileyo:

-Ukuqhelaniswa neFayibha:Ngokuqhelanisa ngobuchule i-carbon fibers ngexesha lenkqubo yokuvelisa, iinjineli zinokunyusa amandla e-cylinder ukujongana noxinzelelo lwangaphakathi.

-Iindlela zokuLawuka:Ubume obukhethekileyo kunye nokulungelelaniswa kweentsinga ngaphakathi kodonga lwesilinda zibalulekile ekuqinisekiseni ukomelela okufanayo kunye nokuthintela iindawo ezibuthathaka.

-Ukhetho Lwezinto:Ukukhethwa kwe-matrix ye-resin esetyenziselwa ukubopha i-carbon fibers nayo idlala indima ekuchaseni uxinzelelo kunye nokusebenza ngokubanzi.

Le ngqwalasela yoyilo olucokisekileyo iqinisekisa ukubacarbon fiber cylinders kwizixhobo zokuphefumla zinokuqulatha ngokukhuselekileyo unikezelo lomoya olucinezelekileyo, lubonelela ngomsebenzi othembekileyo nosindisa ubomi kulowo uwunxibileyo.

Ngapha Kokomelela: Ukujongana nokuChasa iMpembelelo yeeMeko ezingalindelekanga

Ngelixa i-carbon fiber igqwesa kumlinganiselo wamandla-to-ubunzima, ukuxhathisa impembelelo yenye into ebalulekileyo ekufuneka iqwalaselwe kwindawo enzima njengokucinywa komlilo okanye useto lweshishini. Ukuqina okungokwemvelo kweecomposites zekhabhoni fiber kunokubenza babe sesichengeni sokonakala ngenxa yeempembelelo ezibuthuntu. Nangona kunjalo, iinjineli zijongana nalo mngeni ngokusebenzisa:

-Ukuqhelaniswa neFayibha yoBuchule:Ulungiselelo oluthile lwefiber lunokuphucula ukukwazi kwe-cylinder ukufunxa amandla empembelelo kwaye isasazwe ngokufanelekileyo.

-Iinkqubo ze-resin ezomileyo:Iiresin ezenzelwe ngokukodwa ukomelela okongeziweyo zinokuphucula ukuxhathisa komdibaniso kumonakalo ovela kwiimpembelelo.

-Uyilo lweHybrid:Ukudibanisa i-carbon fiber kunye nezinye izinto ezichasene nempembelelo ezifana ne-Kevlar kunokudala isilinda esinikeza amandla aphezulu kunye nokuchasana neengozi okanye ukuhlaselwa kwenkunkuma ngexesha leemeko zongxamiseko.

Ezi nkqubela ziqinisekisa ukubacarbon fiber cylinders azikhaphukhaphu kwaye zomelele kuphela kodwa ziyakwazi ukumelana nobunzima bokusetyenziswa kwehlabathi lokwenyani kwiindawo ezibangwayo.

Ukwamkelwa kunye nezicelo: Ukuphefumla lula ngeCarbon Fiber

Iinzuzo zecarbon fiber cylinderzikhokelela ekwamkelweni kwazo ngokubanzi kwizixhobo zokuphefumla kwiinkalo ezahlukeneyo:

-Ukulwa umlilo:Njengoko kukhankanyiwe ngaphambili, ukunciphisa ubunzima kunye nokuhamba okuphuculweyo okunikezelwa ngucarbon fiber cylinders zixabiseke kakhulu kubacimi-mlilo.

-Ukhuseleko lwamashishini:Abasebenzi abasebenza kwiindawo ezinobungozi njengeendawo ezivaliweyo okanye izityalo zekhemikhali ziyazuza kwisixhobo esilula kunye neempawu zokhuseleko ezongeziweyo.carbon fiber cylinders.

-Impendulo kaxakeka:Abaphenduli bokuqala kunye nabasebenzi bezonyango abasebenzisa izixhobo zokuphefumla ngexesha lokuhlangula okanye iimeko ezingxamisekileyo zonyango bafumana intuthuzelo enkulu kunye nokuhamba okuphuculweyo ngokukhanya.carbon fiber cylinders.

Ikamva liphefumla lula: uTshintsho oluqhubekayo kuYilo kunye nobunjineli

Uphuhliso lwecarbon fiber cylinderuyilo kunye nobunjineli bezixhobo zokuphefumla ngumzamo oqhubekayo. Abaphandi baphonononga iinkalo ezininzi ezithembisayo zokuphucula ngakumbi:

-Udibaniso lweNanotechnology:Ukubandakanya i-nanomaterials kwi-matrix edibeneyo inokomeleza amandla kunye nefuthe lokuchasa ngakumbi.

-Ukudityaniswa koluvo:Ukufakela izixhobo zoluvo

Ixesha lokuposa: Apr-30-2024